In industrial processes, sample conditioning is needed to bring a sample to a sensor under conditions that would allow for it to be accurately measured. When a sample is too wet, hot, over-pressurized, dirty, or chemically aggressive, there is a danger of damaging the sensor. Sample conditioning units will mitigate this risk. They could also help pull a sample from a stationary vessel to expose it to the sensor.

This article provides information that will help process engineers decide if sample conditioning, and what type, is right for their systems.

Oxygen sensors are used in a large number of different applications and under a number of varying conditions. Sometimes, especially when dealing with electronics and some semiconductor applications, they sample within a very clean environment at the appropriate conditions for pressure and temperature. However, that is not always the case.

Many of the samples an oxygen detector is exposed to can be either wet, laden with dust particles, or worse; full of corrosive acids and chemicals that will damage the sensor. In addition, the pressure and temperature of the sample may be too high and would have to be moderated. Samples collected in these adverse environments need to be conditioned before it can be measured.

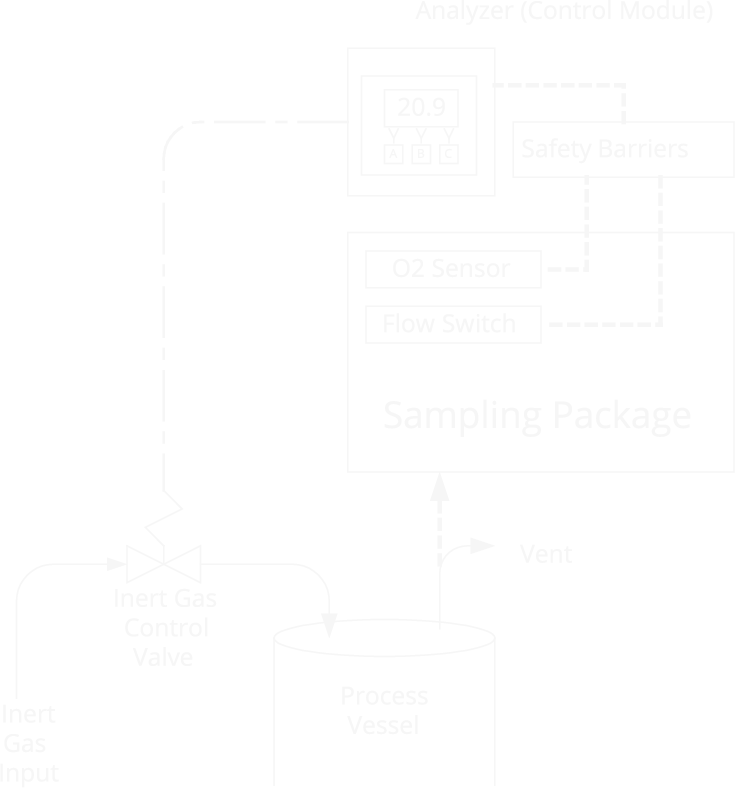

The first thing a sample conditioning box (SCB) needs to do is get the sample to the sensor. If the gas at the measurement point is stagnant, or at too low of a pressure, the SCB will use either a mechanical pump, or a venturi type of eductor, to create a flow that will overcome pressure losses of the filters and other devices and pull the sample to the sensor.

Next, the sample needs to be temperature conditioned; typically, cooled to a level safe for the sensor. It will also be dried, filtered through different size meshes to remove particulates, and may even go through an acid scrubber to remove corrosive chemicals. Due to all the possible different conditions a sample can be in, a SCB needs to be sized and designed individually for the process it is used in. The one-size-fits-all approach does not work well and could waste money.

Sample conditioning boxes (SCB) add a necessary level of safety to the measuring process. If a sensor is not exposed to the flow to be sampled, its reading may be misleading or even zero. If a sensor is being used as part of an inerting system to prevent fires or explosions of a flammable material, a low or zero reading could fool the system into thinking that it is safe and no gas padding would be supplied. A properly designed SCB will have a flow sensor that would alert of a lack of flow, as in the case of a blockage of a line or filter. Another safety feature of some SCB’s used in critical areas is to have redundant sensors in case one fails to perform.

While sampling conditioning boxes are not necessary in every case, their use is critical in many others. A properly designed SCB will help to accurately measure the oxygen level of a process and protect it as intended.

Bacharach’s Gas Analysis Team has been designing and supplying custom SCBs for over 40 years. Our application engineers can help you decide what design is most appropriate for your project.

Read More about inerting control with the Product Quality and Process Safety Whitepaper.

Looking to specify or plan tank blanketing for your processes? Read our Tank Blanketing Whitepaper.